Industrial Hygiene

Qualitative Exposure Assessment (Risk assessment):

- Anticipation and identification of Chemical, Physical and Biological hazards.

- Risk characterization - identifying high risks and prioritizing risk mitigation measures.

- Pre-requisite for developing robust and reliable exposure monitoring plan.

Performed by Certified Industrial Hygienists or Senior/ Experienced Industrial Hygienists.

Quantitative Exposure Assessment (Exposure monitoring) for :

1. Chemicals

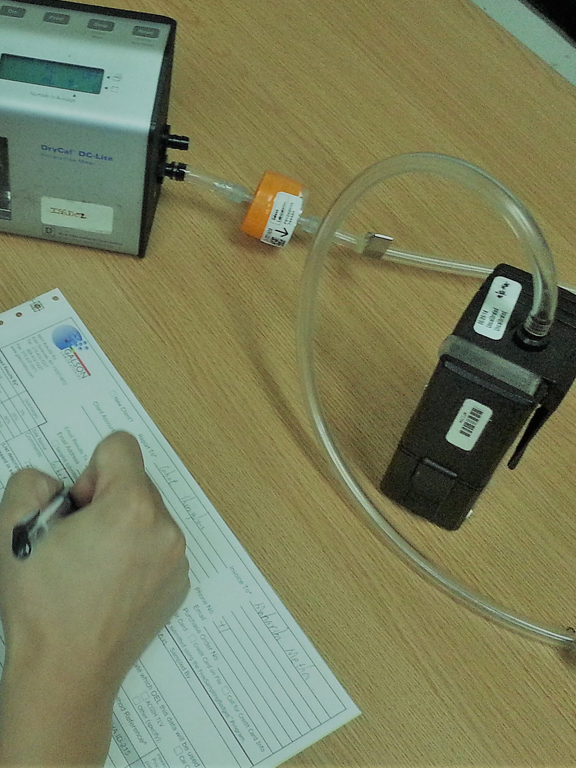

- Industry accepted air monitoring / analytical methods complying with regulatory requirements.

- Most Recent and Calibrated state-of the art monitoring equipment.

- Accredited Laboratories for samples' analysis.

- Results interpretation with regulatory exposure limits and globally recognized guidelines.

- Statistical tools for exposure profile determination/data analysis.

- Recommendations for exposure mitigation and employee protection.

Monitoring strategy development, project onsite support and report review by Certified Industrial Hygienists.

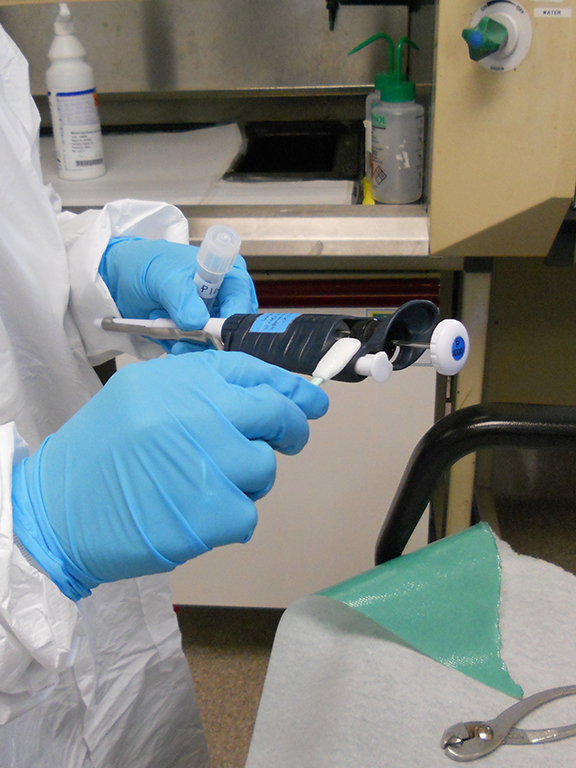

API and surrogate-based exposure monitoring for pharmaceutical companies

2. Noise

- Area sound pressure level mapping and Full shift personal exposure monitoring.

- Exposure evaluation - regulatory limits, corporate/ globally accepted guidelines

- Recommendations to reduce exposures including industry best-practices.

3. Hand-Arm / Whole-Body Vibration monitoring

4. Area heat stress / personal heat strain monitoring

5. Ionizing and non-ionizing radiation assessment

6. Illumination level monitoring

Engineering Controls Evaluation and Design:

- Validating engineering controls (Local Exhaust Ventilation Systems, laboratory fume hoods) with globally recognized standards.

- Validating pharma specific controls (negatively pressured isolators, flexible film containments, Ventilated Balance Enclosures, contained transfer systems).

- Assistance in design/ selection of effective engineering control solutions.

Validated performance for more than 250 engineering control systems

Personal Protective Equipment:

- Hazard assessment

- Dermal protection - selection based on handling and chemical compatibility

- Respiratory protection - Selection , fit testing, training, maintenance and storage

Customized support:

- Industrial Hygiene database management

- Risk assessment software development

- Hazard communication / Industrial hygiene results notification generation

COSHH Risk Assessment software (company specific) developed for leading multinational oil and gas company